Centrifugation

| Technology | |

| |

| Technology details | |

| Name: | Centrifugation |

| Category: | Pre-processing (Separation technologies), Post-processing (Separation technologies) |

| Feedstock: | All materials |

| Product: | Separated products |

Centrifugation is a mechanical separation process which involves the use of the centrifugal force to separate particles from a solution or liquids of different densities according to particle size, shape, density, viscosity and rotor speed. The more dense components of the mixture migrate away from the axis of the centrifuge, while the less dense components of the mixture migrate towards the axis. Next to the separation of solids from liquid, it is possible to obtain separation between two liquids of different densities as well, given that the density difference is large enough.

Feedstock

Origin and composition

The centrifugation method is used to separate two miscible substances. The most common application is the separation of solids from highly concentrated suspensions, which is used in the treatment of sewage sludges for dewatering where less consistent sediment is produced. In the food industries, special centrifuges can process a continuous stream of particle-laden liquid.

Pre-treatment

For a centrifugation, in general no specific pre-treatment is needed since it is used to separate different fractions within a process chain. Sometimes it is combined with other separation technologies like filtration.

Process and technologies

There is a correlation between the size and density of a particle and the speed at which the particle separates from a heterogeneous mixture, when the only force applied is gravity. The larger the size and the larger the density of the particles, the faster they separate from the mixture. By applying a larger effective gravitational force to the mixture, like a centrifuge does, the separation of the particles is accelerated. This way, in industrial and lab settings, particles that would naturally separate over a long period of time can be separated much faster.

The centrifugation speed is specified by the angular velocity, usually expressed as revolutions per minute (rpm), or acceleration expressed as g. The conversion factor between rpm and g depends on the radius of the centrifuge rotor. The particles' settling velocity in centrifugation is a function of their size and shape, centrifugal acceleration, the volume fraction of solids present, the density difference between the particle and the liquid, and the viscosity.

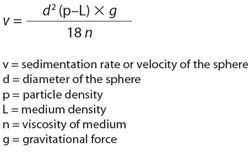

The sedimentation of particles can be explained by Stoke's law. The equation can be used to calculate the velocity of sedimentation based on five parameters:

From the Stokes equation, five important behaviours of particles can be explained:

- The rate of particle sedimentation is proportional to the particle size

- The sedimentation rate is proportional to the difference in density between the particle and the medium.

- The sedimentation rate is zero when the particle density is the same as the medium density.

- The sedimentation rate decreases as the medium viscosity increases.

- The sedimentation rate increases as the gravitational force increases.

Disc-stack centrifugation

Disc-stack centrifugation is used for removing suspended solids from a liquid having a lower specific gravity than the solids. The solids content of the feed is usually in the range of 0.1-10 V/V%.

Basket centrifugation

Basket centrifuges are often called centrifugal filters or clarifiers. The basket centrifuge uses centrifugal force to generate a pressure which forces the liquid through the caked solids, the filter cloth, the backing screen, and finally the basket perforations. The filter cloth retains the solid particles inside the rotating basket while the permeating liquid is continuously discharged.

Solid bowl centrifugation

The Solid Bowl centrifugation principle is schematically shown in the picture on the right. "Solid bowl centrifuges (SBCs), also known as decanter centrifuges, are widely used for various solid-liquid separation tasks, owing to its high-efficiency, small machine footprint and good continuity in production. In the SBC, once the slurry is fed through the centre-positioned feed pipe, solids can rapidly settle onto the drum wall and these settled solids are further dewatered on the conical section of the SBC before being discharged from the product chute. The clarified liquid, so-called effluent, overflows through the bowl weir."[1]

Products

The remaining liquid is called supernatant or supernate. The solids or pellets and the supernatant can be the final product or can be further processed.

Post-treatment

The post-treatment of the precipitate and/or the supernatant is depending on the next steps within the production chain. A typical next step is to dry the solids for further processing.

Technology providers

| Company name | Country | Technology category | Technology name | TRL | Capacity [kg/h] | Processable volume [L] | Relative centrifugal force [g] | Feedstock: Food waste | Feedstock: Garden & park waste |

|---|---|---|---|---|---|---|---|---|---|

| Company 1 | [Country HQ location] | [Technology category (if different sub-categories are defined this has to be specified here, the available categories can be found on each technology page under the chapter Process and technologies)] | [Technology name (the "branded name" or the usual naming from company side)] | [4-9] | [numeric value] | ● | ● | ||

| Company 2 | [Country HQ location] | [(if different sub-categories are defined this has to be specified here, the available categories can be found on each technology page under the chapter Process and technologies)] | [Technology name (the "branded name" or the usual naming from company side)] | [4-9] | [numeric value] | ● | ● |

Alfa Laval

| General information | |||

| Company: | Alfa Laval Corporate AB |

| |

| Country: | Sweden | ||

| Contact: | |||

| Webpage: | https://www.alfalaval.com | ||

| Technology and process details | |||

| Technology name: | AlfaPure | Technology category: | Pre-processing (Separation technologies), Post-processing (Separation technologies) |

| TRL: | commercial | Capacity: | 900-2000, 600-3000, 5000–7000 l·h-1 |

| Processable volume: | L | Relative centrifugal force: | g |

| Rotor type: | Temperature: | 0-80 (15-100) °C | |

| Other: | |||

| Feedstock and product details | |||

| Feedstock: | water and oil-based liquids | Product: | seperated fractions |

Alfa Laval is a leading global provider of first-rate products in the areas of heat transfer, separation and fluid handling. With these as its base, Alfa Laval aims to help enhance the productivity and competitiveness of its customers in various industries throughout the world. We define their challenges and deliver sustainable products and solutions that meet their requirements – mainly in energy, the environment, food and the marine industry.

Alfa Laval

| General information | |||

| Company: | Alfa Laval Corporate AB |

| |

| Country: | Sweden | ||

| Contact: | |||

| Webpage: | https://www.alfalaval.com | ||

| Technology and process details | |||

| Technology name: | Alfie | Technology category: | Pre-processing (Separation technologies), Post-processing (Separation technologies) |

| TRL: | commercial | Capacity: | 230-280 l·h-1 |

| Processable volume: | L | Relative centrifugal force: | g |

| Rotor type: | Temperature: | 5–50 °C | |

| Other: | |||

| Feedstock and product details | |||

| Feedstock: | from water-based industrial fluids, coolants | Product: | seperated / cleaned fractions |

Alfa Laval is a leading global provider of first-rate products in the areas of heat transfer, separation and fluid handling. With these as its base, Alfa Laval aims to help enhance the productivity and competitiveness of its customers in various industries throughout the world. We define their challenges and deliver sustainable products and solutions that meet their requirements – mainly in energy, the environment, food and the marine industry.

Alfie is a simple to use separator: Turnkey, portable, small footprint, centrifugal disc stack separators that remove contaminating oil, grease and solid particles from water-based industrial fluids such as coolants and wash liquids.

Company name

| General information | |||

| Company: |

| ||

| Country: | |||

| Contact: | |||

| Webpage: | |||

| Technology and process details | |||

| Technology name: | Technology category: | Pre-processing (Separation technologies), Post-processing (Separation technologies) | |

| TRL: | Capacity: | l·h-1 | |

| Processable volume: | L | Relative centrifugal force: | g |

| Rotor type: | Temperature: | °C | |

| Other: | |||

| Feedstock and product details | |||

| Feedstock: | Product: | ||

The company description goes here.

Open access pilot and demo facility providers

Patents

Currently no patents have been identified.

References

- Centrifugation in Wikipedia

- Centrifuge in Wikipedia

- ↑ Changzhi Bai, Hangil Park, Liguang Wang, 2021-08-15: Measurement of solids concentration in aqueous slurries for monitoring the solids recovery in solid bowl centrifugation. Minerals Engineering, Vol. 170, 107068. doi: https://doi.org/10.1016/j.mineng.2021.107068